The Shift Selectors That Kick Productivity Into High Gear

Your vehicle’s transmission is key to keeping things moving in the right direction. If you’re operating a safe and efficient vehicle on or off the highway, you’re likely using an Orscheln Products shift selector. Original equipment manufacturers (OEMs) all over the world trust our experts to deliver precise motion control solutions built to perform.

We’ve been moving things in the right direction since 1946. Over the years, we’ve evolved and changed with industry standards, but the quality of our products and services hasn’t changed a bit. Shift selectors are one of our most widely used control systems. Take a few minutes to see why we’re a go-to for manufacturers nationwide.

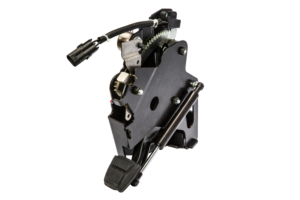

Electro-Mechanical Shift Selector

Orscheln Products can provide complete systems or just components for both OEM applications as well as the aftermarket. We provide Push Button, T-Handle Release, and Top Push Button Release configurations.

Electro-mechanical shift selectors include an electronic sensor that communicates with the transmission, or they use an electronic shift selector panel to communicate with an actuator that shifts the transmission mechanically. With new developments in battery electric vehicles, those shift mechanisms can be any combination of these systems or fully electronic.

What It Does

In addition to providing clear, satisfying shifts, our electronic mechanical shift selectors are perfect to connect your transmission with your selector in close quarters. This makes it a popular option for many COE designs and other complex challenges.

How It Does It

As advanced as vehicles are, mechanical parts still make up the majority of components on vehicles. Our electro-mechanical shift selectors give you one less part number to keep track of. By connecting your transmission to a drive-by-wire system, you’re connecting the engine to the transmission for flawless and reliable execution from your vehicle’s transmission control module (TCM).

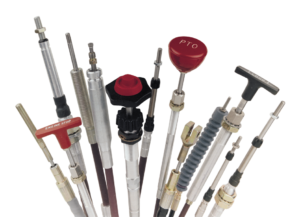

Mechanical Shift Selector

Orscheln Products started creating solutions long before transmission control modules were a thing. Transmissions are one thing, like engines, that get rebuilt, recycled, and reused in the market. There are rebuilders and remanufacturers out there that find areas where a mechanical shift selector is needed. Knowing more about the specific transmission will allow us to research a solution for your needs.

What It Does

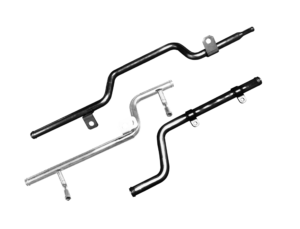

Our mechanical shift selectors include more complex physically connected linkages. We typically recommend these for heavy-duty or high-performance applications. By connecting your transmission to your selector with a physical part, you’re ensuring a strong, lasting connection.

How It Does It

We design every solution using computer-aided design (CAD) files from the manufacturer’s design team. To get the most control for mechanical shifting systems, we take precise measurements and work in tandem with the OEM’s design team. Each mechanical shift selector is designed to give crisp, reliable responses for many applications on and off the highway.

Which is right for you?

Choosing one type of shifter over the other comes down to the type of input your transmission requires or what the designers had in mind when developing your vehicle. There are occasionally specific requirements of the transmission that may impact the type used.

Mechanical shift selectors are best for ensuring a crisp, reliable shift every time. There are many benefits to our simple, refined design. From total performance to anti-theft properties, there are many problems these simplified designs are built to overcome.

Electro-mechanical shift selectors are currently the most widely used solution in this segment from Orscheln Products. That’s because our plug-and-play design allows for easy installation and customizability for almost every application connecting a driver to the transmission via a drive-by-wire system.

What are you working with?

Based upon space, performance requirements, and interior design, the different types of shift selectors can be customized to meet the intended use and user comfort. We want the function to perfectly align with the form of every component we create.

We use state-of-the-art CAD-assisted tools to create every solution. By supplying our engineers with the right information, we can build you a fully customized solution or simply talk you through ways to improve your design. Either way, we’re an open book when discussing shift selectors, so stay in touch if you run into any head-scratching moments from initial design to final production.

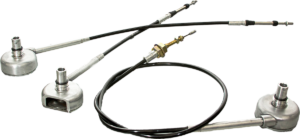

T-Shifter for Allison 1000 & 2000 Transmissions

There are many things to keep in mind when ordering these transmissions due to their vast amount of applications. Here are 3 key things to remember when you talk to an Orscheln Engineer:

- A shift system will consist of a shift lever, a push-pull control cable, and a transmission connection kit.

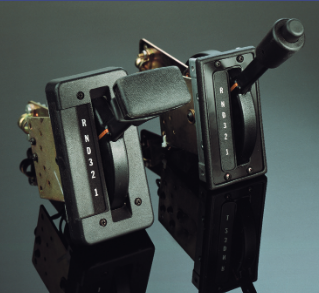

- To configure a shifter part number, start by determining the automatic transmission model. Then, choose the type of shift handle like the “T-Shifter” or “NG” (if applicable). These two specific types are available for the Allison Transmission 1000 and 2000 series: the “T” lever with two-finger release knobs.

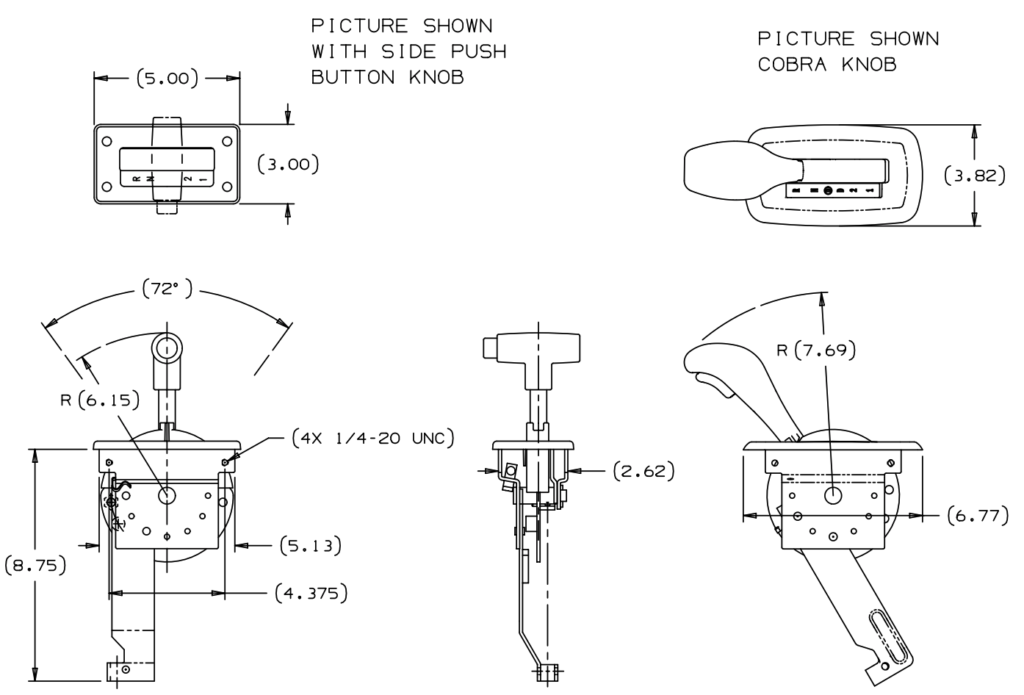

- An “NG” shift selector is available with a side push button or Cobra-type lever handle.

NG Shifter for Allison 1000 & 2000 Transmission

The Allison 1000 and 2000 can be mounted in many different ways for different purposes. To make connections efficient and easy to operate, Orscheln offers two configurations of the NG Shift selector. See which shift selector is right for your application.

Cobra

The shift knob of a Cobra handle is designed to be ergonomic for left and right-hand operation. It also happens to look like the head of the deadly snake! With an optional push button or solid heads, the Cobra makes shifts crisp and quick on horizontal applications. These are commonly used in on- and off-highway vehicles such as construction, agricultural equipment, and parcel handling.

Side Push Button

Reminiscent of a certain car that came with a bird on the hood, our side push button shifters are used on more than just muscle cars. You’ll typically find these in applications that require a directional shift to a specific operator position. You can find our solutions on horizontal and vertical applications with the same strength and reliability included on every Orscheln Product.

Shifters for Allison Transmission Legacy AT/MT/HT

The T-Handle and Push Button shifters are trusted designs for heavy freight and transit systems. They have numerous options, all of which can be expertly assembled by many Felsted® Assembled System Technology (F.A.S.T.) distributor.

Shifters for Legacy Allison Transmission Models AT, MT, HT, and Others.

We classify legacy models as models that are out of production from the OEM. But as we all know, many units are still in operation due to their easy maintenance and aftermarket possibilities, such as our Orscheln F.A.S.T. distributors. Our distributors are equipped to design and build similar options with their direct link to our full manufacturing capabilities.

Asking Questions, Creating Solutions

There are some customizable features that can be done to better suit an application. And, based upon the geometry of the shift pattern, special gate configurations may be required. This is when we like to get creative. Often, we’ll see simple gear patterns. But when you factor in specially designed systems for multiple transmissions with multiple engines, things can get interesting very quickly.

Whether your vehicle requires a mechanical or electromechanical shift selector, every solution benefits from having multiple eyes on every prototype. Our custom solutions can be designed to promote ease of use, efficiency, and strength. We use the optimal alloys, plastics, and connectors to ensure accurate, responsive selections for thousands of hours in service.

Durability Meets Design

Here’s where we don’t mind bragging a little. With this many great minds under one roof, manufacturers are able to breathe a sigh of relief as they ask for help designing the future of transportation. Many of the solutions we create support small businesses, freight companies, and families on the road. That’s why we take the quality of our work very seriously. Technology has changed since 1946, but our core values of quality and service never will.

Design

Before anything gets created, you need to talk about it first. To manifest your custom solution with a designer trusted by thousands of OEMs worldwide, just give us a call. Our engineers are happy to talk about everything from requirements to limitations you’ve been running into. We’re always excited to help others create better products through education.

Testing

This is where we truly put your solution to the test. Our in-house labs test prototypes for requirements until destruction. This means that we build our components to exceed expectations for use by carefully considering ways to improve your design.

Production

Our network of distributors is a great way to get acquainted with Orscheln Products. We can take orders to fulfill reordering and even get to know your production schedule to automatically refill orders. This means you have a friend in the motion control solutions industry, ready to help you make the most out of your vehicle.

Creating Custom Solutions

Every custom solution we design is completely unique to your exact specs and will pass the respective certifications for legal use. The typical turnaround time for a completely custom order can range depending on requirements, material availability, and desired turnaround time. Typical turnaround times for these products is between 3 to 6 months to go from CAD files to your assembly line. We are also able to offer even faster turnaround times from a special network of distributors.

Find Your Shift Selector Fast

Our worldwide F.A.S.T. distribution network allows us to offer affordable shipping costs, quick turnaround time, and a reliable flow of components when manufacturers need them most. We share our designs throughout our vast network to make ordering your custom solution simple and easy. Talk to a F.A.S.T. distributor in your area for fast, reliable service.

History in the Making

To understand the reliability of our products, it’s best to look at our heritage for revolutionary motion control solutions. Our story began on the banks of the Missouri on an everyday delivery route. As a driver arrived back to his truck after making a delivery, he found the truck rolling away, headed straight into the river. Uncle Al, our mechanic, created a custom solution on the spot for what evolved into Orscheln park brake systems.

Since that fateful day, our mission has been to provide the backbone of America with the strongest solutions for support. By learning from and collaborating with other industry leaders, we’ve become an integral part of OEMs that keep America moving in the right direction every day.

Get Your Shift Together

Ready to drop a gear and disappear? You’ll need a trusted shift selector source! Learn from our decades of experience and shift your production into high gear with an Orscheln engineer.

To get the latest info and insights from the orscheln experts, sign up for our monthly newsletter!