Our Gold Standard of Production

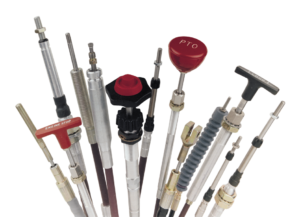

Times have changed in our decades of engineering and so have manufacturer’s needs. Orscheln Products keeps up with the highest specifications and regulations for our entire array of products. Our engineers work tirelessly to ensure our solutions meet the product qualification requirements for our customers. So let’s take a look at what goes into making sure our solutions meet your needs.

Building Reliability and Relationships

To ensure Orscheln designs a custom solution that fits your requirements, our engineers will work meticulously with your team and learn everything about what you need for your solution. Before you talk with an engineer, make sure to bring as much information as you can to the conversation.

How to talk to an engineer about your needs.

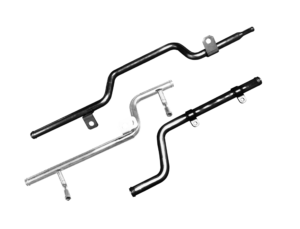

Orscheln is truly a one-stop shop. That means we create your product completely in-house from concept to design to qualification, and production.

With extensive understanding of our capabilities, Orscheln engineers can effectively design and fulfill your specific requirements. To ensure the success of your project, we urge you to provide comprehensive information about necessary materials and operational standards during our discussions. Moreover, we are committed to maintaining transparency and adhering to any confidentiality obligations to uphold the integrity of our solutions.

This includes everything from proprietary prototypes to classified government designs. We also use DFARS-compliant materials from trusted suppliers in our manufacturing facilities worldwide if necessary. Here’s how we test your product to your requirement.

Land

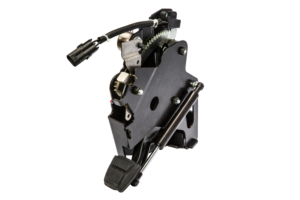

To make sure your solution will perform on and off the highway, your engineer will ask a few questions. What are your input and output loads? Does it need to stand up against dust? What are the temperatures you need it to perform in? How many cycles will this solution need to run in its lifetime?

This is where you’ll need deep knowledge about how your product needs to operate. Our highest-spec products reliably meet Military standard 810. So you can be sure Orscheln has what it takes to meet even the most stringent product qualifications.

Sea

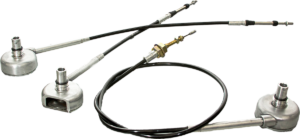

If your solution will be living on the water, we’ll need to make sure to meet your necessary product requirements. In this case, your engineer at Orscheln will ask some very specific questions pointed to marine vehicles.

How deep might this solution be submerged? What temperatures will it need to operate in? What pressures will this solution need to withstand? We also have the ability to waterproof your products that spend any time in or around the water to ensure durability. But as we look to the skies, there are even more qualifications to keep in mind.

Air

When your product needs to defy gravity, you can’t settle for subpar specs. Orscheln is trusted by the FAA and DOD to meet every current requirement including DO160 to ensure airworthiness. Here are some basic questions that you’ll need to answer to get your solution cleared for takeoff.

- How much force will be applied in your application?

- Is your craft pressurized or not?

- What anti-icing requirements will this product need to meet?

There are many more questions manufacturers will need to answer regardless of where their product needs to perform. So when you talk to an Orscheln engineer, be prepared with any and all product requirements you need your solution to meet.

What we test for

Now that you know what we’ll ask, let’s check out how we make sure your solution meets every requirement. All of our solutions meet the highest standards required by using the latest available technology. So wherever you need your product to perform, we’ll use each necessary test to give you components you can rely on.

Mechanical Endurance

We refer to this as the stress test. To test for endurance we make sure your product runs the gambit. We test for durability and efficiency throughout the product life cycle, regardless of 10,000 cycles or 1,000,000 cycles.

There are a few very specialized tools we use to ensure your product meets the toughest mechanical endurance requirements. Including a dedicated specialty test stand to ensure desired endurance capability.

Operating Vibrations

One of the most damaging elements of daily operation is vibration. In this environmental simulation, we use the aforementioned tests in this portion as well. In addition to key tests using a vibration coil.

To meet the required combined vibration spec, our engineers use an in-house vibration coil and monitor the effects on the solution using a vibration control system.

Sand and Dust Resistance

This is the one of few capabilities that Orscheln currently requires an outside testing lab. These experiments are crucial to ensure that your product can keep operating in a harsh dusty environment.

To test for sand and dust resistance, we put the prototype into a chamber surrounded by fans on all sides that blow dust and sand at high speeds. We test to Mil 810 and SAEJ1455 standards using approved media.

Our engineers ensure that the prototype can withstand abrasion, and doesn’t allow any leaks through cracks or crevices. This ensures that any product that may be exposed to dust and sand can perform in the harshest conditions for the life of the product.

Corrosion inhibition and Humidity

This is one of our most flexible testing measures. Our in-house lab is capable of testing for various specs from ASTM to SAE standards. Our lab is capable of various tests to measure the effect of temperature, humidity, and thermal shock. We test products for temperatures ranging from -70C to 170C and relative humidity levels from 10% to 98%.

We can test against chemical corrosion in products as well. Since every solution may be subjected to any number of chemicals, we test this on a case-by-case basis. Talk to an engineer about how your product will need to be tested and the specifications you need it to meet.

Waterproofing

Water doesn’t just affect our seafaring customers. That’s why our engineers make sure to know every potential condition your product will be operating in. For example, our throttle controls may be used in your skid steer or forklift, and those vehicles may spend a considerable amount of time outside. To make sure all of our solutions stand up to the elements, we test for various specifications of waterproofing.

For this, our lab technicians use submersion and pressure testing modalities. These tests include factors such as water pressure, and potential depth of functionality. We have the capability to include ice resistance in these tests as well.

Ice Resistance

Testing for ice resistance is a lot more complicated than it may sound. For this testing, we combine a few modes to create an icing environment and simulate operation. Depending on where and how your solution will operate, we test for specific environmental factors.

We combine waterproofing and thermal shock testing to ensure the desired durability as well. In the air, we test solutions such as aircraft cable assemblies to ensure they are able to operate safely in extreme conditions.

All of our tests are tailored to your product and your needs. Every solution we supply is backed by over 75+ years of experience and the combined expertise of our engineers that make it all happen.

Our Process

While all these advanced testing measures may seem complex, our engineers use the same scientific method tried and trusted by everyone from 3rd-grade science classes to NASA astronauts. Simply put, we test it until it’s right. We test, break, and problem-solve for every solution until it’s ready for production. This is how a product goes from prototype to production.

Prototyping

After you talk with an Orscheln engineer about your solution and the desired specs, we’ll spend time designing and creating a prototype. Depending on your timeline, your engineer will work with our labs to schedule testing. Before testing days we’ll build a custom outline that we’ll use in testing to record our testing.

Testing

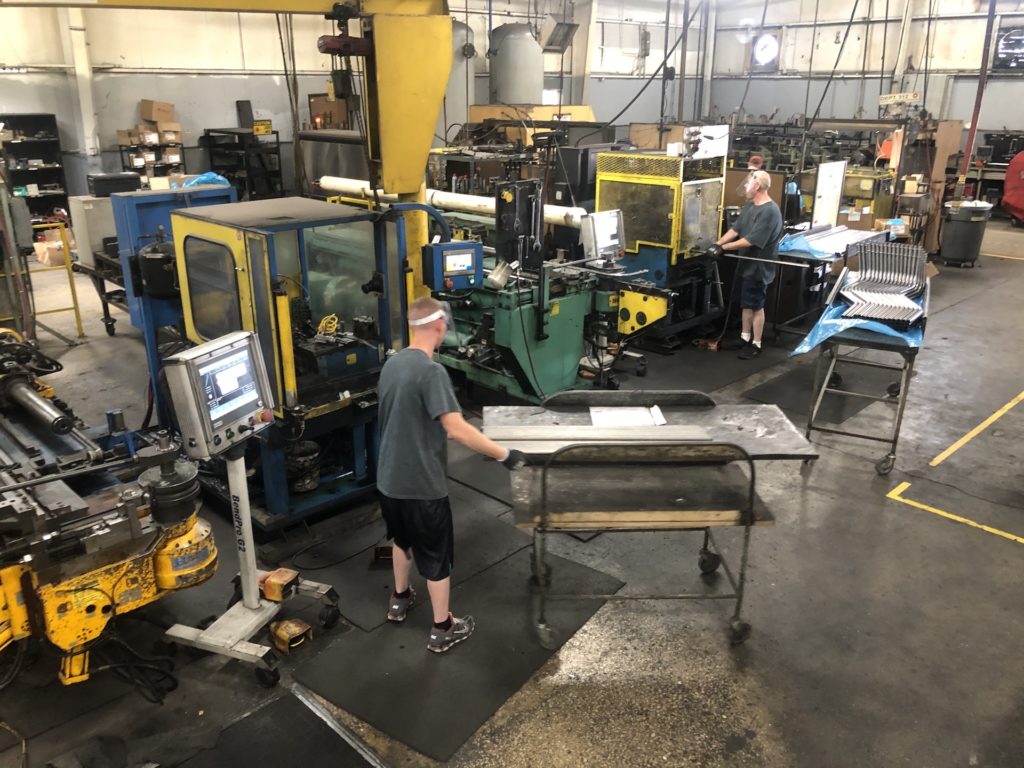

During each of the aforementioned testing methods, we’ll record our findings and include you in any test phase you desire. In our 15,000 sq ft facility we test each prototype individually to ensure that findings are accurate and data stays secure. After your prototype meets the desired specifications and regulations, we notify you of our results and talk about putting together a production plan.

Production

To bring your solution to the production line, we take the exact specs of your successful prototype and create copies. Our in-house CAD, CAE, and FEA programs ensure that every product we create is an exact copy. But Orscheln isn’t known for products that are just good enough. We go above and beyond by manufacturing high-quality products every single time.

Perfection Comes Standard

Orscheln Products is ISO 9001:2015 and AS9100D and ISO 14001:2015 certified. We also maintain an FAA PMA Approved QMS. Our APQP development process incorporates best practices including design and process FMEAs, design reviews, validation testing, control plans, and PPAPs. Our attention to detail ensures that every component we produce is right the first time, every time.

From design to prototype to certification, to full-scale production, Orscheln is capable of meeting even the most rigorous product qualification requirements. Talk to an engineer about your needs, or contact any of our offices worldwide to learn why OEMs trust the Orscheln gold standard.