Finding a Trusted Battery Coolant Tubing Manufacturer for Your EV Innovation

As the market of medium to heavy-duty electric vehicles emerges, new innovations move the world forward every day. While the world moves, Orscheln moves with it. Our industry knowledge and history of excellence make Orscheln the battery coolant tubing manufacturer of choice for OEMs worldwide.

EV manufacturers trust Orscheln for solutions because cutting-edge innovations can’t rely on second best. Our customers come to us not only for the quality of our service and products, but for the reliability and durability of their custom solution.

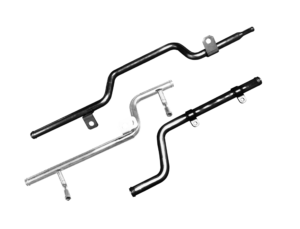

When it comes to battery coolant tubing, rubber, and plastic lines just won’t do. That’s why you need the sturdiest solution. Our custom-bent stainless steel lines can withstand the high pressure and demands of daily use. We know because manufacturers have trusted our engineers to keep their trucks on the road and out of the shop for decades.

Why Choose Orscheln as Your Battery Coolant Tubing Manufacturer of Choice

Orscheln has the expertise to keep the next generation moving cleaner. We put over 70 years of experience to work in all of our trusted products for the medium and heavy-duty electric freight industry. Manufacturers know that any innovation can’t be a reality without a blueprint. So for your solution, we start with a design.

Orscheln’s process starts with a routing model. This requires a CAD model of your vehicle to find the most efficient route paths for your lines. After the route model is generated in CAD, our engineers design a solution to match your vehicle’s parameters and the required performance. Once the CAD model is complete, we begin the prototype phase.

Our engineers love this part of the process. In the prototype phase, we focus on getting the correct bend points and the right thickness of tubing for your solution. After we plot the bends and create the desired tubing, our CNC machines get to work creating prototypes for inspection before production.

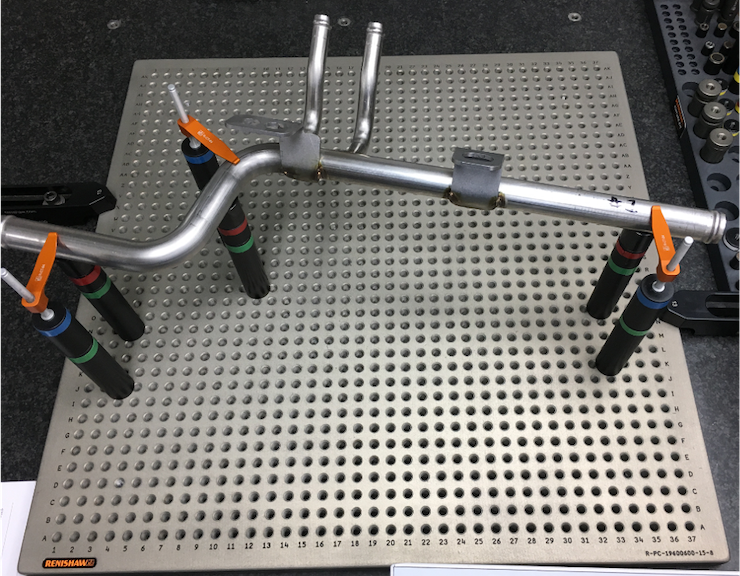

In the testing phase, we use the Zeiss Bridge CMM and 2 Roamer Arms CMM. With a measuring accuracy down to 7 ten-thousandths of an inch, this CMM ensures accurate bends and measurements for your solution. The Roamer arms and Zeiss bridge work in tandem to create bend programs, IGES, and CAD files of our prototype. The Roamer Arms communicate the exact specs to our bender during the first piece inspection and automatically adjusts the program. Once we create a successful prototype, we can produce thousands of copies with identical measurements, bends, and finish!

Orscheln can accommodate almost any demand, but we do limit minimum order sizes to 1000 units. Here are other things to keep in mind when making Orscheln your battery coolant tubing manufacturer of choice.

Battery Coolant Tubing Manufacturer Capabilities

It’s important to find the right manufacturer for your components. This is where Orscheln stands out as a leader in the EV industry. Our experience in various industries allows us to use techniques that other manufacturers can’t. Keep the following in mind when you work with our engineer at Orscheln.

Custom and standard applications

When we design your components, our aim is to be as informative and helpful as possible. We can make custom tubing to meet even the most demanding requirements. But for most applications, we offer standard options for your components. This table shares our standard tube bending capabilities.

| Tube Size | Bend Radius |

| 3/8” OD | 2”, 3”, 5”, 7.5” Center Line (CL) |

| 1/2” OD | 3”, 4”, 4.72”, 5” CL |

| 15mm OD | 4”, 5” CL |

| 5/8” OD | 1”, 1.5”, 3”, 5” CL |

| 3/4” OD | 1”, 3.375”, 4”, 5”, 6” CL |

| 1” OD | 1.5”, 4”, 5”, 6” CL |

| 1 ½’” OD | 2.69”, 3”, 3.346”, 5” CL |

It’s important to keep a few key things in mind when choosing your battery coolant tubing manufacturer. All of our tubing measurements are of the outside diameter. If you don’t see your desired size, talk to an engineer about our custom sizing options. If you do require custom sizing, we’ll walk you through additional tooling that may be required.

Diverse end forms for your battery coolant tubing

Our process uses automated end forming to create industry-standard ends for your tubing solution. To connect your system, you’ll need to consider what you want your end form to be. Use this table when talking over your design with an Orscheln engineer.

| Hose bead per SAE J1231 |

Common size tubes 5/8”, 0.75”, 1.0” & 1.5” |

| 37° flare (JIC) per SAE J533 | 0.5”, .75”, and 1.0” |

| O-Ring face seal per SAE J1453 | 0.5”, .75”, and 1.0” |

| 45° single flare per SAE J533 (inverted flare nut) | 0.75” |

More sizes are available as well. Additional tooling may be required to suit your needs.

Industry-leading techniques for battery coolant tubing solutions.

When we say industry-leading, we mean it. On any job site in America, the chances are high that you will find a medium-to-heavy-duty electric trucks using Orscheln hardline tubing. From design to final product, we are a battery coolant tubing manufacturer you can trust for durability and efficiency.

Industry leaders choose Orscheln for their electric vehicle components because we start by using the right material for the right job. To meet your needs we use CNC bending and drilling, laser cutting and our in-house tooling shop to design the best tubing. But when it comes to putting your coolant tubing system together, we make it easy.

With automated end and bead forming, we are able to easily create your connector and seal solutions with the push of a button. We use robotic welding for most of our products. But we also offer manual welding and brazing as the design requires. The option for manual brazing and welding is a rare option that keeps the biggest names in the medium and heavy-duty trucking industry coming back to Orscheln for OEM solutions.

Protecting your battery coolant tubing by going the extra mile.

While powder coating has become a standard across many battery coolant tubing manufacturers, we go the extra mile to make sure your tubing stays insulated and protected. Our process starts by cleaning your tubing in a high-pressure and high-temperature wash station. We then charge the material in an electrostatic current and apply the powder coat. We then bake off the excess at almost 400 degrees and allow the material to cool before applying a rust inhibitor to the inside of the product. Just like any part of the production process, we can even customize the color of your powder coating for your specific application.

Investing in the future of EV transportation.

Electric Vehicles are the fastest-growing segment of the transportation industry. From the consumer to the commercial level, new innovations change the way the world moves every day. This is why Orscheln is proud to lead the charge by creating durable, capable solutions for the future of zero-emission transportation.

A Proud Supporter of the NACFE

As an OE manufacturer, Orscheln stays up to date with regulations and studies by the North American Council for Freight Efficiency. We learn from the technology and practice analysis to make our customer’s products the best in the industry with the latest knowledge.

We took what the NACFE found in their studies on deployments, haul reports, and cost of ownership to fine-tune our development of our customer’s solutions. We are helping the industry navigate to a zero-emission future by supporting manufacturers and research initiatives alike.

Run on Less

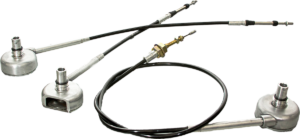

Run on Less events were established to create a showcase for advancements in freight efficiency. Run on Less Electric, or RoL-E 2021, demonstrates how emerging technologies like electrification benefit bottom lines and the environment. Orscheln is a proud supporter and sponsor of RoL-E. Providing components for manufacturers evolving the future of transportation.  With our support, the 13 trucks that participated in RoL-E 2021 drove over 6900 miles, made 1,692 deliveries, and saved 11.72 tons of CO2. We provided the participants with state-of-the-art throttle controls, shift selectors, and fluid transfer tubes for every step of the way. Orscheln continues to support the NACFE and RoL-E in future studies and the development of their groundbreaking Electric Depot.

With our support, the 13 trucks that participated in RoL-E 2021 drove over 6900 miles, made 1,692 deliveries, and saved 11.72 tons of CO2. We provided the participants with state-of-the-art throttle controls, shift selectors, and fluid transfer tubes for every step of the way. Orscheln continues to support the NACFE and RoL-E in future studies and the development of their groundbreaking Electric Depot.

Trust our history for your innovation.

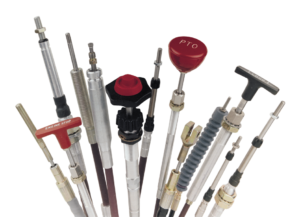

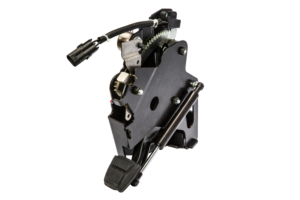

For over 70 years Orscheln has supplied manufacturers with components that keep the world moving. Orscheln’s family of products has grown to include Park Brake Systems, Control Cables, and more. Our products are trusted by more than just on and off-highway manufacturers. We also supply manufacturers in Aerospace, Defense, Marine, and specialty markets.

Our roots began in the US at our Moberly Missouri facility. And we meet international markets through our global manufacturing and sales facilities in Rugby, England, Chennai, India, and Shanghai, China. No matter where you’re innovating for the future, we have the capability and the experience to meet your needs.

Manufacturers around the world trust Orscheln because of our continuous commitment to quality, leading-edge products, and superior service. As the world moves toward a zero-emission future, Orscheln is proud to supply manufacturers with OEM-quality solutions. With our experience and expertise, it’s not hard to tell why Orscheln is the industry battery coolant tubing manufacturer of choice.

Start engineering the future with Orscheln

The transportation industry moves fast. This is why Orscheln is proud of our team of engineers and skilled workers. Together they provide our customers with low turnaround time and high-quality solutions.

If you’re part of the electric truck evolution, talk to an engineer today about our array of products already helping the truck industry. And learn why Orscheln is the industry choice for battery coolant tube manufacturing.