An Overview of Aircraft Cables at Orscheln

For companies in the aviation industry, it’s important that your aerospace vehicles feature aircraft cables designed and manufactured using the utmost quality.. As the most-used linkage in flight control systems, it’s critical to partner with a company committed to utilizing the most advanced technology and materials to ensure precise control and long-term lasting safety.

As a leading manufacturer of airline cables, Orscheln Products is the premier choice for both standard and custom aircraft cables for the aviation industry. Whether you’re an equipment manufacturer, an engineer, or an aftermarket customer, our team has capably designed and built aircraft cables for over 50 years and provided solutions for a variety of different aerospace vehicles.

On our blog this month, we’re taking the time to highlight our aircraft cable products and all of the reasons to choose Orscheln for your design and manufacturing needs.

Our Aerospace Capabilities

From our headquarters in Moberley, Missouri, Orscheln Products designs and produces a variety of mechanical control systems. With an emphasis on quality and customer service, we offer a number of resources dedicated specifically to the design and production of aircraft and military controls. Specifically, we design aircraft control cables in the following aerospace vehicles:

- Commercial aircraft

- General aircraft

- Military and defense aircraft

- Light jet

- Helicopter

- EV Aircraft

- EVTOL, Electric Vertical Take Off Landing

- And experimental aircraft

The team at Orscheln Products makes it a point to offer the capability of full customization with any aircraft cable order. Because of this focus on customization, we’re capable of fulfilling the specific needs of a given customer. We will work with you to design and manufacture equipment to your exact specifications.

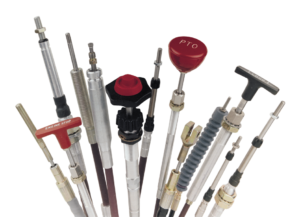

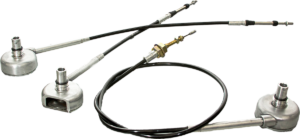

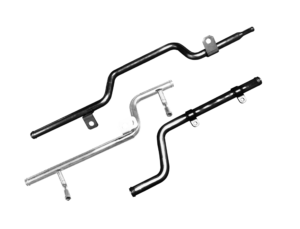

All across the globe, Orscheln produces a wide variety of solutions for aircraft, including conventional push-pull cables, ball bearing push-pull cables, and lanyard-type cables. Some common uses for these solutions are in flight control, with others used in redundant systems for emergency landing gear deployment, ram air turbines, and emergency braking.

Additionally, we also design and manufacture the Felsted™ and ACCO control cable product line alongside our standard brake cable product line. With this approach, we offer a broad and diverse line of cable offerings that are competitive with any manufacturer in our industry.

Our Process

You can trust in the reliability and quality of our aircraft cables, beginning with the very first stages of our design and manufacturing process. The first step in our process is the concept phase, where we identify the specific needs of the customer and lay out a roadmap for the project. We are in constant communication with customers about their requirements and specifications for the project, allowing us to begin the computer-aided design (CAD) work. These requirements include:

- Length

- Load

- Compression load

- Tension load

- Fire requirement

- Life cycle

- Slide force requirement

- And Backlash.

When it comes time for design, our team always utilizes a consultative approach with our customers to address their specific needs. Because of our focus on customization, the order of the process will vary by customer. If a customer has a drawing for a specific part, that will help speed up the design process. Once our team develops a design, we will send it back for customer approval, move into the quoting process, and build a prototype.

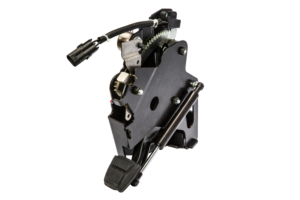

When it comes time to build your specific aircraft control cables, Orscheln Products’ offers a wide range of manufacturing capabilities. These include aspects such as die-cast and injection molding, stranding and extrusion, or stamping and plating.

Our experienced professionals construct the control cables within our dedicated manufacturing cell. We perform all assembly in-house, with some components purchased from outside resources. We also utilize CNC tube bending and CNC welding to manufacture fluid transfer tubes.

In total, the lead up to developing these parts and releasing them into production takes roughly 7 to 10 weeks. If you’re an OEM or aftermarket customer looking for control cables for aircraft applications, or in the market for a partial or full aerospace control system, we have you covered.

Compliance & Testing

Certifications are a very important part of a quality management system. From initial design through prototype, certification, and production, we strive to operate with the highest level of integrity. This means that we not only meet all federal and international regulations with our aircraft cables but exceed them. Every Orscheln Products Test Engineer is committed to the proper design and function of each Orscheln product.

Qualification testing is available through both our in-house facility and the use of outside certified laboratories. For outsource testing, we focus on capabilities such as dust, altitude, and fire resistance. When it comes to in-house testing, Orscheln Products’ 15,000 sq. ft. lab houses all testing operations built to prove each product meets internal and/or customer specified requirements.

We offer a wide array of different in-house testings, which include:

- Temperature variation (high to 350 degrees Fahrenheit, low to –60 degrees Fahrenheit),

- Vibration

- Shock

- Endurance

- Waterproofness

- Icing

- Load limit

- Salt spray

- Ultimate load

- Humidity

- Fluid susceptibility.

Compliance is another aspect of production that Orscheln takes very seriously. Our entire team understands the amount of compliance the aerospace industry faces. For this reason, Orscheln maintains a dedication to ensuring all of our manufactured products pass FAA Compliance.

This approach ensures that our OEM and aftermarket customers that purchase our products meet the many technical specifications needed to pass inspections and regulations. We include all of these perks when you purchase solutions from Orscheln Products.

Orscheln Products has experience working with FAA-PMA assemblies, FAA, and customer conformities. Our constructions meet the requirements of FAR 23.1411(2000 degree flame test) and FAR 25.853 (burn test). We maintain a business system in compliance with Title 14 CFR, Part 21, subject to FAA inspections, and have completed engineering development programs and validated them to MIL-STD-810 and RTCA/DO-160. We are DFARS and ITAR compliant, and we have a DMIR on staff.

Additionally, Orscheln’s team of professionals also understands the tight packaging spaces available in aircraft designs. Therefore, we specialize in custom-designed systems that meet the requirements of each individual customer.

Why Orscheln?

Experience

Since our inception over 75 years ago, our company has maintained a commitment to providing clients in the aerospace and military industries with cutting-edge products. In that time, we’ve become a global leader in designing and constructing numerous different product lines, including aircraft cables.

Aircraft control cables specifically were added to our product offering in 1998, with the acquisition of Acco Industrial Controls. Through this acquisition, Orscheln Products gained aircraft cable manufacturing expertise that dates back to the late 1930s. Since this time, our product line has been expanded and diversified to include the latest technological advances and materials.

Additionally, Orscheln offers the benefit of familiarity with a wide variety of different applications. We have control cables on multiple aircraft and helicopters, as well as numerous case studies and data sets with our control cables upon request. This data includes information on aircraft cables such as temperature testing, dust testing, endurance testing, vibration, shock, waterproofness, and salt testing.

Global Reach

Orscheln has the unique distinction of earning international recognition for dependable quality, which clients throughout North America, Europe, China, and India have all benefited from.

We also hold offices in all of these locations and offer a distributor cable assembly program, called F.A.S.T. ®, with over 100 locations worldwide.

Each of our locations holds dedicated team members that hold the same high standards as our location in the United States. With our F.A.S.T. ® program, customers can rest assured that they’ll receive products of impeccable quality both in low volumes and with a speedy turnaround.

Communication

Throughout the process, our team will make sure that customers are never in the dark regarding their aircraft cable purchase. From the moment of first contact all the way through completion, our team will remain in consistent contact with customers to ensure that we complete their project to their exact specifications.

Even after the sale, when we’ve already sent the first production parts, we will follow up with you regarding any open item and touch base periodically for general check-ins. And if you have any questions throughout the process, we have dedicated team members ready to assist anytime, whether virtual or in-person.

Contact Orscheln Today for all of your Aircraft Cable Needs

If you’re a business in the aviation or military industry and looking for aircraft cables, you’ve come to the right place. Orscheln Products maintains an unwavering commitment to providing each of our service markets with a distinct blend of care, expertise, and customization. We’ve worked for decades to become an international leader in aircraft cable design and manufacturing.

From concept to design to manufacturing, you can count on our experts to provide exceptional service and lasting aircraft solutions. With global reach and experience managing projects across a wide variety of industry niches, you can rest assured that Orscheln Products has the capabilities to make your development project a success.

So, if you’re an OEM looking for high-quality aircraft cables for your aerospace vehicle, look no further. At Orscheln Products, your project is our priority! Contact us today, or take advantage of our virtual engineer to engineer service.