What are Redundant Aircraft Systems & Why are They Important?

It’s always critical to have a safety net. That fact is true both in everyday life and every bit as so in the aerospace industry. When it comes to aerospace, redundant aircraft systems provide that safety net by acting as a reliable back-up plan in case of faulty equipment or an emergency situation.

Ideally, a company would never have to think about redundant aircraft systems because it would mean all components of an aircraft are operating properly. However, because aerospace companies must prepare for any and all possible outcomes relating to their aircraft and equipment, dependable redundant aircraft systems prove to be an invaluable asset.

For over 40 years, Orscheln Products has partnered with companies around the world in both the aerospace and defense industries. Based in Moberly, Missouri, with offices in India, Europe, and China, we’re a global leader in the design and manufacturing of redundant aircraft systems, in addition to countless other product lines.

Read on to receive an overview of redundant aircraft systems, why they’re important, and Orscheln’s process for developing redundant systems.

What are redundant aircraft systems?

Simply put, redundant aircraft systems serve as a backup to the primary operating system. The term “redundant” is the key here, as the systems are an exact duplication of all critical functions and components of all the aircraft’s different primary operating systems.

Redundancy is a standard practice in engineering, as it increases the reliability of a system in the event one of its functions or components fails. Ideally, you’ll never need to use a redundant aircraft system, because it means that your primary operating system is operating efficiently and without issue. However, in the event that the primary system has a problem, you can use your redundant (also called a “backup”) system to restore normal or emergency operating function.

A redundant aircraft system will deploy in the event any failure takes place with your primary system. It may take effect if a single component fails or if your primary operating system experiences complete failure. In this way, you can think of a redundant aircraft system as similar to having a spare tire for your car. You hope that you never need to use it, but it’s there ready in case of an emergency.

Because of this, having a redundant system available helps add an extra layer of reliability and safety to any aircraft, aerospace, or defense vehicle. Even though you may not ever need it, having that security and peace of mind makes it worth the investment.

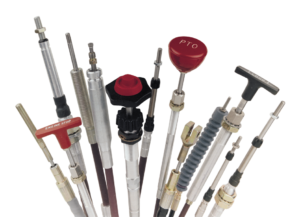

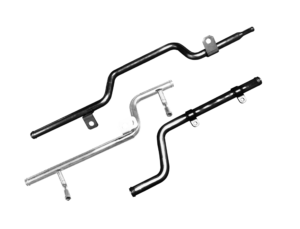

Some of the most common redundant systems that we manufacture at Orscheln Products include:

- Emergency landing gear release

- Ram Air Turbine

- Emergency oxygen

- Emergency braking

- Emergency fuel shut off

Why are redundant aircraft systems important?

We understand that original equipment manufacturers or aftermarket customers may have cost concerns in regards to purchasing systems that they might never use. However, you can never understate the importance of your aircraft’s safety and reliability. The fact is, no matter the quality of your equipment, some breakdowns are both unpredictable and unpreventable.

When operating your aircraft, there’s always the possibility that the external conditions can cause a breakdown, such as a lightning strike or hail. Additionally, there are many different moving parts within an aircraft that all need to operate effectively in perfect unison. Because there are numerous components and functions in an operating system, it’s complicated to ensure that every single one will function properly throughout the lifespan of your aircraft.

With that said, there’s a reason why experts consider aircraft travel to be the safest form of long distance transportation. It’s due in large part to the fact that each operating system within an aircraft has redundancies within them. It’s impossible to account for every single possible outcome that can happen before, during, and after flight. However, having duplicate systems throughout an aircraft ensures that no single malfunction can cause a potentially catastrophic result.

Because of the importance of redundant aircraft systems, it’s integral to ensure that the systems you use are both high-quality and built to last. Backed by over 40 years of experience in this particular field, Orscheln Products has served countless aerospace and defense industry OEMs and aftermarket customers around the world. Our name has become synonymous with both value and longevity, and you can find our systems in aircrafts wherever you go.

Orscheln’s Redundant Aircraft System Process

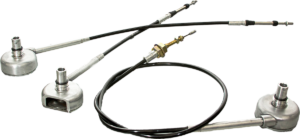

What makes Orscheln Products an ideal partner for any redundant aircraft system is not only our experience, but also our ability to provide customized solutions based on the unique needs of our customers. In fact, we design and manufacture all of our redundant systems, both for jets and propeller aircrafts, in commercial and general aviation, based on the needs of our OEMs, instead of only offering a standard product (although we do offer current and standard systems upon customer request).

Consulting with client across the globe

Because of our focus on customization, our dedicated redundant aircraft systems engineering team starts each project by consulting with our OEM or aftermarket customers. With four offices around the globe, we’re capable of meeting customers and initiating projects regardless of where they’re located.

These consultations hold great importance, because they allow us to collaborate with our customers and develop a concept for the project that will influence subsequent design and manufacturing decisions. During this time, we review all specifications, special requirements, and loads required by the project. Before beginning a project, it’s important to note that we require a minimum order quantity of at least 10 pieces. We can work with you on 1 off prototypes if needed.

Design

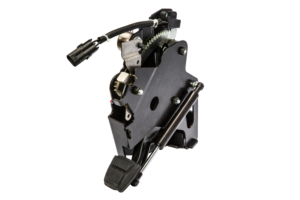

Once we’ve reviewed the specifications and verified a plan for the project, our team creates a design fit for function and purpose, while following strict QMS and AS9100 guidelines to deliver that product. Like with our other available aircraft controls, all of our current redundant systems are mechanical and include a microswitch, which provides a signal that illuminates a light indicating the redundant system is in use.

Manufacturing

A redundant aircraft system and their assemblies involve a combination of multiple parts. This is another area where working with an experienced team like Orscheln comes in handy. As a company, we have experience across a wide range of parts and components. That means that when the parts come together in assembly, we’re capable of fulfilling customer requirements based on their individual needs.

Orscheln performs all redundant aircraft system assemblies in-house in our dedicated manufacturing cell. During the manufacturing phase and throughout your project as a whole, the team at Orscheln makes it a point to stay in consistent communication with OEM and aftermarket customers to ensure the proper completion of all goals and product stages.

Testing

Once we complete the manufacturing portion of your redundant aircraft system project, the next phase is certification and testing. One of the main pillars of Orscheln Products as an organization is our commitment to ensuring a quality product delivered when you expect it. We never sacrifice quality for the sake of speed, and we strive to operate with the highest level of integrity. As part of that commitment, we ensure that each system adheres to all local, federal, and international regulations and guidelines.

When it comes to testing your redundant aircraft system, our Test Engineers will work to verify that every design and function of your system operates as outlined in your project plan. We also perform all of our qualified testing through either our 15,000 sq. ft in-house testing facility or through outside certified laboratories.

From start to finish, you can expect the full timeline of your redundant aircraft system project to last about 2 to 3 years in total. With that said, much of that estimate depends on the customer and how long it will take to get all of the proper specifications as well as an approved design.

Contact Orscheln Today for all of your Aircraft Cable Needs

If you’re an OEM or aftermarket customer looking for redundant aircraft systems, Orscheln Products is ready to partner with you. Serving both the aerospace and defense industries, we provide support to companies around the globe from our headquarters in Moberly, Missouri, as well as our offices in Europe, India, and China.

What sets Orscheln apart from others in our industry is an unwavering, company-wide commitment to providing each of our service markets with the care they deserve. Utilizing an approach centered around innovation, collaboration, and experience, customers have turned to us for decades for their aerospace design and manufacturing needs.

From the first point of contact through project completion, you can count on our experts to provide exceptional service and lasting redundant aircraft solutions. With global reach and experience managing projects across a wide variety of industry niches, you can rest assured that Orscheln Products has the capabilities to make your development project a success.

So, if you’re an OEM looking for high-quality redundant aircraft systems for your aerospace or defense vehicle, look no further. At Orscheln Products, your project is our priority! Contact us today, or take advantage of our virtual engineer to engineer service. If you’re looking for a specific part with a quick turnaround, submit a request through our website or reach out directly to our sales team.”