The Not-So-Simple Science Behind Our Simple Innovation: Dipstick Assemblies From Orscheln

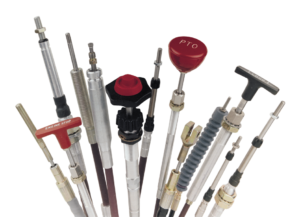

Orscheln is proud to produce the most advanced motion control solutions on the market today. OEMs trust our engineers to give them exactly what they need for their vehicles, from the most complex computerized systems to heavy-duty cables built for the long haul. While they may not sound glamorous, dipstick assemblies from Orscheln are trusted to maintain accurate fluid levels over millions of miles and thousands of hours of use. Keep reading to learn more about the fascinating science behind fluid-level indicators.

Locked and Ready

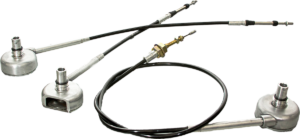

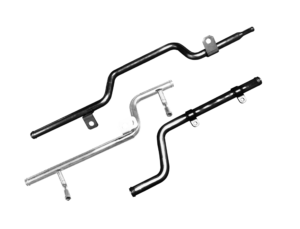

The custom locking dipstick from Orscheln is the first available patented Twist2Lock™ style dipstick on the market. Due to the custom nature of this product, we have an array of stainless steel materials, end forms, fittings, and custom brackets to fit almost any vehicle. This is also why customers enjoy choosing Orscheln.

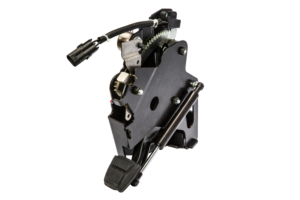

With additional research, development, and industry changes, Orscheln adapts and uses the most advanced technology to create innovative solutions for fluid management, including battery coolant lines, fluid transfer, and other specialty applications where corrosion is a concern. We also can design and produce custom mounting brackets or jump tubes as required. Orscheln offers stainless steel fluid transfer lines that utilize many similar features to our tried-and-true dipsticks that have been trusted by manufacturers around the world for decades.

Designing a Dipstick

Not to brag, but we sure can bend some metal! There’s a lot more than meets the eye when it comes to fully custom dipstick solutions. We start with CAD and physical measurements to plan the routing. We recommend that our customers supply any CAD files or spec sheets that may be helpful in this stage.

If that is not possible, it’s up to our engineers to learn the style/size of the cap and spout, as well as the engine/transmission model. We’re better designers than conversationalists, so to make it easy on both sides of the production line, most customers come to us with clear designs and a full array of important files.

Measure Twice

Our entire array of products is a cut above the rest. That’s because our engineers only work with precise measurements. To accurately measure your entire dipstick assembly, we use the length from the interface with the engine/transmission to the place you want to locate it. We also take any obstacles into consideration as we design a generic routing system. As simple as dipsticks may look, they’re actually just as complex to create as our other motion control components. That’s why our engineers are always available to help before, during, and after we create your solution.

Every vehicle has a unique layout and sometimes very specialized needs when it comes to fluid management. As a leader in our market, we set the standard for quality, customization, and style. Dipsticks and tubing products are a major part of the product lines we offer at Orscheln, and we intend to be the “go-to” company when you need an innovative solution. With USA-based operations and a global footprint, we are the place to turn for fluid level indicators, dipsticks, and other fluid transfer solutions. We pride ourselves on innovating even the simplest components to improve every aspect of the motion control industry.

New Tricks for Old Dipsticks

Dipsticks really haven’t changed that much since the first self-propelled vehicles hit the road—until our engineers got a hold of one. The first Twist2Lock™ dipstick was developed in the early 2000s by Felsted Products, who eventually merged with Orscheln. This merger led to the birth of our worldwide FAST distribution network and the dawn of a new age for dipsticks.

With our strong distribution network and revolutionary dipstick designs, Orscheln continues to make our mark as one of the top manufacturers of custom dipstick solutions in the world. As simple as it looks, this product line continues to be our fastest-growing product line. We continue to create innovative solutions every day across all of our product lines. But when it comes to our dipsticks, there is always more than meets the eye.

Our Dipstick Assemblies

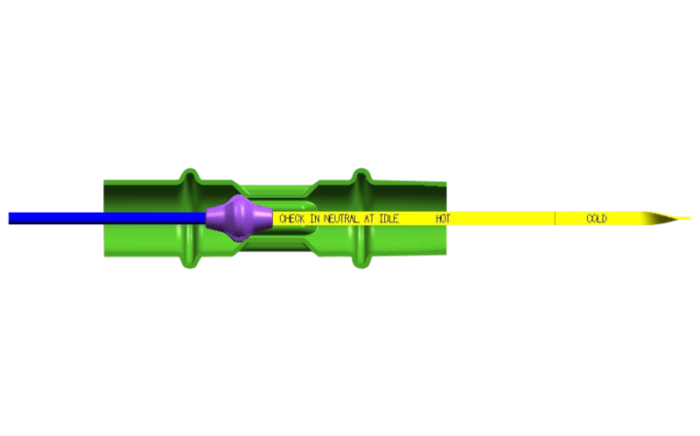

Most Orscheln dipsticks have a patented push or Twist2Lock™ cap and spout that create a secure and sealed fit. Each is designed with security, accuracy, and reliability in mind. We offer twist to lock dipstick assemblies ranging from F1 to F4 to suit most vehicle requirements. Each dipstick assembly comes with unique qualities and potential applications, so look through our selection to find the one that’s right for you!

Push 2 Seal

The Push 2 Seal™ Fluid Level Indicator clearly displays check or check/fill requirements for light- and medium-duty engines when the costs and qualities of the Twist2Lock design are not necessary. You can order these solutions as a standalone dipstick or a complete system. They can also be customized to your specific requirements.

These dipstick assemblies come in P1 through P3 tube inside diameter size ranges:

- P1 ranges from 8.13mm to 10.15mm

- P2 ranges from 10.16mm to 12.06mm

- P3 ranges from 11.81mm to 14.10mm

Each of these classifications comes with unique typical operation conditions and performance. For our more heavy-duty applications, we look to our Twist2Lock dipstick assemblies.

F1 Twist2Lock

This Twist2Lock™ Fluid Level Indicator design is for check, check/fill, or fill-only applications on medium- and heavy-duty engines and transmissions. We manufacture each of these as a complete system and offer custom solutions for every customer. Tubing sizes for these assemblies go up to 15mm. Any larger requirements will mean a different assembly for your application.

Each of the Twist2Lock™ dipstick assemblies come to our customers as fully calibrated, ready -to-install components. These are also created with custom bends, indicators, and blade sizes for every application. This ensures that every solution we create comes with the quality and reliability that make Orscheln a leader in motion control components.

F2 Twist2Lock

Similar to the F1 system, the F2 Twist2Lock™ system is designed for medium- and heavy-duty vehicles. Unlike the F1, these offer a wider range of customization capabilities for tubing and handles. These dipstick assemblies are available with the T handle or round cap options. We also offer polymer or metal tubing based on the temperature of the area where the tube is designed to be routed. Tubing can range from 0.5 inches to 1 inch outside diameter.

F3 Twist2Lock

What makes this Twist2Lock™ system unique is the tube sizing and the round cap that comes standard on every F3 dipstick assembly. Just as the other classifications, these are created as complete systems for medium- to heavy-duty engines and transmissions, and they can all be customized to your exact specifications. Tube sizes range from 1 inch to 1.5 inches using outside diameter. Tubing material is limited to metal due to the typical usage of these dipstick assemblies.

F4 Twist2Lock

When OEMs need our biggest and baddest dipstick assemblies, we have the F4 Twist2Lock™ system. Just as in the F3, the tubing is limited to metal. Customization is limited to routing, end fittings, and measurements. Our customers look to the F4 for the largest tubing available ranging from 1 inch to 1 ⅝ inches. This allows for accurate measurements for larger reservoirs and applications that require a lot of fluid.

Key Benefits of Our Dipstick Assemblies

With increasing pressures and temperatures inside engines, this locking mechanism helps to prevent the stick from becoming loose, lost, or leaking. Orscheln also offers vented versions to minimize the impact of pressure buildup and maximize longevity of use.

We create every Orscheln dipstick assembly as a capable, custom-made system. That means the stick and tube are designed and created together. This ensures that the “stick out,” or the area where the measurement is taken, is in the correct spot every time.

FLI or Dipstick?

We’ve referenced both dipstick assemblies and fluid level indicators throughout this passage, so here is the main difference. Typically, dipsticks are used for engines and transmissions, but there are many applications for fluid level measurement such as pumps, tanks, reservoirs, etc. Anywhere you want to check the level of fluid in a tank, you’ll need a fluid level indicator, or FLI.

Orscheln uses the term FLI internally because our products are more than just dipstick assemblies. We refer to these indicators differently because, as we develop solutions to accurately measure fluid levels, we have the need for custom configurations for unique customers and applications. The term “fluid level indicator” is the most accurate way of describing the actual use of our product, but we typically use the term “dipstick assembly” interchangeably.

Tested, Proven, Unique

Our dipsticks are tested using the latest CMM technology for tube bending accuracy, leak testing, sealing, and forming details. While every bend is double-checked through physical measurements, we maintain the highest-quality products by matching up CAD files with our in-house measuring machines. Our unique manufacturing process also allows us to create accurate dipsticks alongside

precisely bent tubing. This ensures the right fit and accurate readings every time.

Our dipstick assemblies are easily recognizable with mounting and hardware that keeps everything secure and easily visible. Our durable plastic cap and spout are designed to be attractive, functional, and useful while protecting the posts. Metal and plastic are the last things you want in your tank, transmission, or engine. That’s why Orscheln goes the extra mile by molding the cap and spout onto the tube. This ensures a secure connection regardless of temperature, pressure, or any other conditions your vehicle may operate in.

Do Your Dipstick Right

Orscheln prides itself on being the leader in dipstick technology. Year after year, we maintain our commitment to providing our customers with durable, functional, and customizable solutions for working-class vehicles everywhere. When OEMs need the most accurate fluid levels, they trust Orscheln for industry-leading solutions that make us a household name on and off highways around the world. Talk to an engineer to design yours, or get your solution quickly through our massive FAST distribution network.