Automatic Transmission Shifter & Other Shift Control Systems from Orscheln

Most people don’t think about all of the moving parts required to set a vehicle into motion. It’s much easier to simply step into your vehicle, turn on the ignition, and go—rather than make your head spin thinking about all of the different systems within your vehicle. However, defense and commercial markets can’t afford to have that same mindset.

These markets and others rely on vehicles (both on– and off-highway) to meet the varying demands of their partners. Even one malfunctioning part can lead to significant delays, downtime and costly repairs. That’s why customers within the commercial and military markets require rugged, reliable solutions to properly operate their vehicles long-term.

One area where this need is particularly evident is within a vehicle’s shift control system. Most are familiar with manual and automatic transmission shifters—AKA the device one uses to shift their vehicle into a different gear. However, it’s critical to know why the whole system matters and the importance of having a quality partner for new projects, installations, and any upgrades to shift controls.

Offering over 50 years of experience serving customers in commercial and defense markets, Orscheln Products is precisely the partner you need. Read on to learn more about shift controls—as well as our design and manufacturing process!

What is an Automatic Transmission Shifter?

Every vehicle contains both a drivetrain and a powertrain. Though many people use these terms interchangeably, there is a difference between the two. The drivetrain contains all of the parts needed for your vehicle to move—while the powertrain uses power from the engine to give power to the wheels.

The drivetrain and powertrain collaborate with one another, and your transmission plays a crucial role in that process. Specifically, it helps to transfer power from the engine to the driveshaft—allowing your vehicle to accelerate and decelerate.

To put it simply: drivers will use an automatic transmission shifter to select the specific gear position within a commercial vehicle. While there are several different types of vehicle transmissions out there, Orscheln focuses specifically on automatic transmission applications.

The Difference Between Automatic & Manual Transmission

Driving a vehicle requires a large range of speeds.Your transmission helps channel the power generated by the engine into appropriate amounts of torque. This way, a driver can accelerate from a complete stop—or prevent the engine from becoming overworked when operating at highway speeds.

The difference between a manual and automatic transmission shifter is apparent in the name. When shifting gears, your transmission needs to temporarily disconnect from the engine—doing so using a torque converter. In a manual transmission, the driver will do this individually by pushing the clutch pedal.

In an automatic transmission, the vehicle will use its sensors to determine the right point to switch gears—and do so using internal oil pressure and a torque converter. Most commercial vehicles use automatic transmissions as opposed to manual, as most drivers find them easier to operate.

Our Shift Control Production Process

If you’re looking for an automatic transmission shifter or other shift control systems, you can expect a collaborative process right off the bat. We try to gain a thorough understanding of the unique needs of each OEM or aftermarket customer before starting work. This helps give us the necessary guidance in order to make a proper recommendation.

In some cases, a standard shift control product may provide the solution you need. That said, customers can take advantage of the design and manufacturing capabilities of the Orscheln team. We can use this ability, and our extensive knowledge, to offer a single custom component or a whole custom shift control system.

If you do need a custom design, we’ll ask you to send a description of your component or system, as well as any specific requirements.

Each OEM and aftermarket customer has the option to configure their shift control system with position sensors, switches, and mounting brackets—depending on their application needs. Other custom options include vehicle interlock flexibility and illuminated shift position strip. Gathering this information helps our engineering team put together a model of the product.

From there, our team will maintain an open line of communication to ensure you have everything you need before manufacturing begins.

Testing & Quality Assurance

Shift control systems have a lot of moving parts. And when you have moving parts, that means you also have plenty of wear surfaces. Because your automatic transmission shifter plays such an important role in vehicle operations, endurance, and longevity is key.

In this regard, Orscheln shift control systems maintain high acclaim within our industry today. We’re thankful to be known as the most rugged, reliable shifters on the market, suited to the most demanding vehicle duty cycles. One way that we mitigate problems with our shift control systems is by using proven, high-quality materials. For example, each shift control uses case-hardened or through-hardened materials on many high wear components.

However, the most effective method we use for measuring quality and durability comes through extensive testing. Depending on the requirements of the customer, we customize our test protocols to ensure that the product they receive is built to last and meets all specifications. All customers can expect their product or system to undergo significant environmental and endurance testing as well. This may include, but is not limited to:

Temperature/Humidity:

- Thermal Cycling: -70°C to 170°C

- 10% to 98% Relative Humidity

- Thermal Shock: -70°C to 170°C

Vibration:

- Sine, Random, Shock, Accelerated, & Combined Environment

Dust:

- SAE J1455 Optional Method, Suspended

Mechanical:

- Durability/Life-Cycle/Efficiency

- Ultimate Strength

Shift Control Systems at Orscheln

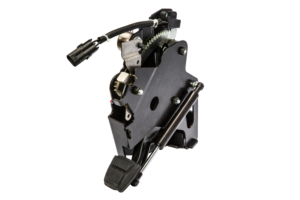

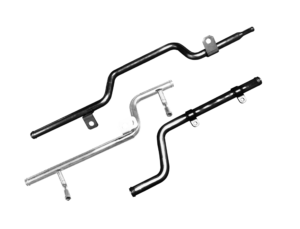

At Orscheln, we offer standard mechanical and electro-mechanical shift control products in addition to custom shift control systems for automatic transmission applications. An entire shift control system contains a shift control lever, mounting hardware, a control cable, and a transmission connection kit.

Orscheln began focusing on combining commercial transmission shifters with control cables as a system all the way back in 1972. Since then, we’ve continued to grow and expand our capabilities. Based in Moberley, Missouri—with offices in India, Europe, and China—Orscheln now provides both standard and custom shift control systems to companies around the world.

Our experience and expansive knowledge base have played a key role in our ability to expand. More than that, however, our ability to design and produce high quality automatic transmission shift systems—for a wide range of applications—has truly set us apart. In fact, Orscheln shift control systems have a configuration suited to just about every automatic transmission that has a mechanical shift arm!

Add in our global network of F.A.S.T. distributors, and we’re truly capable of providing creative solutions that fit the unique needs of countless OEMs and aftermarket customers. Some of the most common applications for our shift control systems include:

- On-highway vehicles

- Vans

- Buses

- Off-highway vehicles

- Haulage tractors

- Military trucks

- Specialty commercial vehicles

- Allison 1000/2000, Eaton, GM, and Ford Transmissions

- Delivery Vehicles

- Transfer Case

- F-N-R (Forward-Neutral-Reverse)

- H-L (High/Low)

- Up-Down

- 5th Wheel

- Fast/Slow

- PTO (Power Take Off)

- Friction Throttle Control

Additional Shift Controls

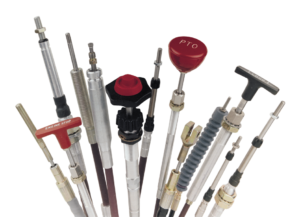

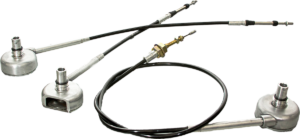

Beyond heavy-duty commercial automatic transmissions, Orscheln also designs and manufactures custom applications for pumps, valves, and other specialty applications, in addition to mechanical push-pull cables, transmission connection kits, and related hardware and accessories.

We offer cable-controlled, lever-operated valve controls that provide both versatility and rugged operation. With a remote valve operator control system, operators can benefit from increased efficiency brought about by remote operation, ease of use, and economical size.

For more demanding applications—such as those found in agriculture, construction, and specialty truck services—customers may benefit more from heavy duty levers in standard and push button, gated configuration.

Pump control systems are available on both Side Push Button and T-Handle Release configurations. Each comes with a highly durable design crafted from steel and other rugged materials to ensure longevity in addition to a positive locking detent system to significantly reduce the chances of the control being knocked out of place.

Bottom line: all of the shift control systems at Orscheln feature designs that ensure longevity and simplicity. Whether you need an automatic transmission shifter for your vehicle or valve and pump controls for heavy duty applications, our products can help make your operations more efficient.

Contact Orscheln Products Today for Shift Control Systems or Components!

If you’re an OEM or aftermarket customer looking for an automatic transmission shifter component or system, Orscheln Products is ready to partner with you. More than military and commercial, we serve a variety of industries with a global reach. From our offices in Moberly, Missouri, Europe, India, and China, we can provide standard or custom solutions to fit your application.

What sets Orscheln apart from others in our industry is an unwavering, company-wide commitment to providing each of our service markets with the care they deserve. Our entire team emphasizes collaboration and combines it with an innovative approach and unrivaled expertise. These are just a few of the reasons that customers have turned to us for decades for their design and manufacturing needs.

From the first point of contact through project completion, you can count on our experts to provide exceptional service and durable products. At Orscheln Products, your project is our priority!

Contact us today, or take advantage of our virtual engineer to engineer service. If you’re looking for a specific part with a quick turnaround, find a distributor near you and submit your request.