Orscheln Products for Off-Highway Applications

Orscheln produces components OEMs rely on to keep the world moving. While you can find many of our solutions on the highway daily, our products are also found where the pavement ends. To keep operators in control wherever motion happens, Orscheln products are trusted around the world. Keep reading to find the right component for your on- or off-highway application.

What Does Off-Highway Mean to Orscheln?

Off-highway can mean many different things to our customers. We’re proud to provide solutions that keep fighter jets flying high and ships sailing the high seas. However, the solutions we’ll focus on in this feature keep life moving on solid ground.

These off-highway applications all have one common thread that runs through them. Mechanized movement is building the future every day. Our products keep progress moving forward, with reliability and efficiency as the main focus of every solution.

Construction

To build the future, tradesmen need reliable tools throughout a job site. This is where you’ll find a great deal of Orscheln’s off-highway products. To build cranes, tools, and trucks found on construction sites worldwide, we supply a few key products:

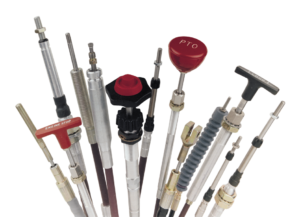

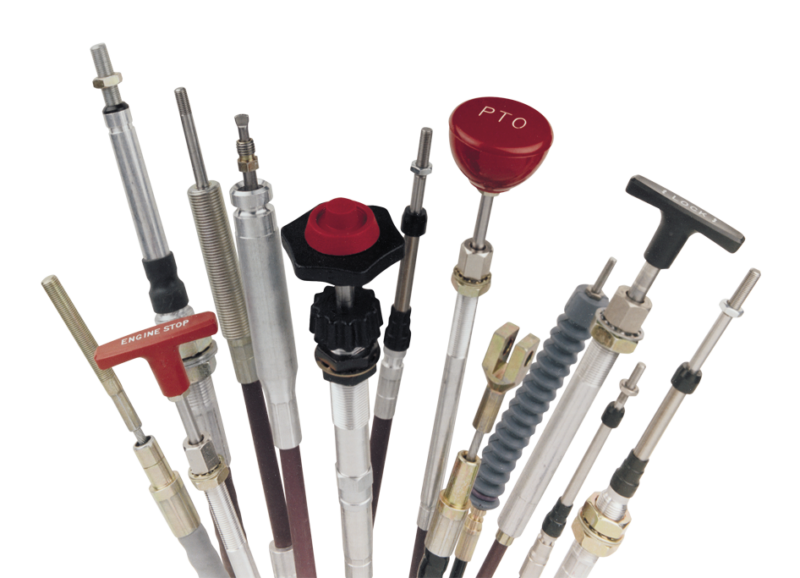

Control Cables

These are some of the most widely used components for any vehicle found on a construction site. To function reliably, these components are crafted with the most advanced innovations. Here are a few defining qualities of an Orscheln control cable:

Core Construction

High Performance (HP) 1 x 7 coated cores are available in 3, 4, and 6 Series cables. HP cores use a proprietary coating over a 1 x 7 wire rope. This construction offers improved flexibility and higher push loads than armor core construction.

For more rigorous demands, solid stainless steel cores are available in 3 Series push-pull, universal, positive lock, and PTO cables. Tension cables use a 1 x 19 HP coated core, while 8 Series push-pull cables utilize an armor core for maximum durability and use.

Conduit Jackets

The outside of every cable is protected with thick-walled polymer jackets extruded onto the stranded liner for maximum cable strength. Standard HP cable material is polymer molded to a dark maroon color. HEFT 2 jacket, used in high-temperature applications, is a nylon-based material molded to a satin black color. Your Orscheln engineer will help you specify which can be used based on the operating standards for your vehicle.

Rod and Sleeve Bearings

Orscheln utilizes an exclusive polymer rod and sleeve bearing to improve efficiency, sealing, and cable life. By preventing metal-to-metal contact between the rod and sleeve, less friction leads to reliable use for years. Our production lines accurately align the rod with the seal to further ensure superior sealing and longer cable life.

Learn More: Control Cable Specifications

Cables Used on Construction Applications

The construction of our control cables is only half the story when it comes to off-highway motion control. Where and how each cable works defines the correct cable for our customers. Here are a couple of control cables commonly found in construction equipment around the world:

Light Duty Cables

Orscheln light duty control cables are made from robust steel strong enough to handle applications that plastic or thin sheet metal can’t. LD cables include input features such as rotary, twist-to-lock, and linear control with friction adjustment. The Orscheln factory and F.A.S.T. regional distributors can provide custom cables for each control.

Push-Pull HP Cables

Orscheln’s push-pull cables include 4 different series of cables, ranging from Series 3 to Series 8. These cables include standard and HEFT ratings that are indicated by either a maroon (standard) or black (HEFT) sheathing. These cables are an industry favorite because of their low backlash and high efficiency under load.

Shift Controls

You can find shift controls on many vehicles throughout a construction site. From simple, push-button electromechanical selectors to complex Shift-X-Wire systems, Orscheln does it all. Our shift controls focus on providing the smoothest, most reliable selections for automatic transmissions. Here’s how Orscheln makes shift happen on job sites around the world:

How to Order Shifters

First things first, an OEM needs to install the right shifter. A shift system will consist of a shift lever, a push-pull control cable, and a transmission connection kit. An accessory like a mounting tower or wedge can also be included. Here’s how we configure shifters for off-highway applications.

To configure a shifter part number, we first determine the automatic transmission model. Next, you’ll choose the type of shifter, such as “T-Shifter” or “NG”. Our two shifter types are available for the Allison Transmission 1000 and 2000 series: the “T” lever with two-finger release knobs, and the “NG” shifter, available with a side push-button or Cobra-type lever handle.

Agriculture

While cars race by on the highway, farmers keep the world fed at a different speed. Off the highway, Orscheln Products keeps machines moving in fields all around the world. These are the common components we supply to feed the world’s needs:

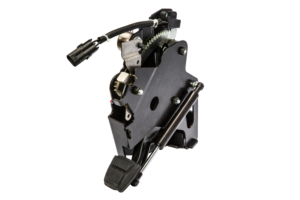

Throttle Controls

Each throttle control we create delivers a precise signal that interacts with the engine’s electronic fuel management systems. Our fast-reacting pedals provide smooth operation and ensure a durable, longer life. We use polymer components to create a lightweight, effective connection between operators and their machines. These pedals are lightweight solutions for a world in motion. While our polymer technology is amazing, we back pedals up with steel base plates if required. Here are a few ways we keep throttles accurate for off-highway vehicles.

Drive By Wire Innovations

While Orscheln has been providing throttle controls long before computerization, our solutions remain on the cutting edge of technology. The majority of throttle controls we supply for off-highway agriculture use drive-by-wire technology. This minimizes the parts count and maximizes the versatility of our throttle controls.

Hall-Effect Sensor

The brains behind every Orscheln throttle control. The Orscheln hall-effect sensor has dual, electrically independent, and independently programmed sensors. Redundant sensors meet FMVSS requirements and allow for fast, accurate, and correlated verification of sensor angle by the engine’s electronic fuel management systems.

Pedal Clusters

Also referred to as a “pedal box,” a pedal cluster is fabricated with the electronic throttle and brake pedal custom-made into a metal assembly. This assembly will save engineering and development time upfront and can eliminate over a dozen parts for the OEM assembler. It also saves considerable time at the vehicle assembly line.

Park Brake Levers

Orscheln Products over center style park brake levers and foot pedal levers have been the industry standard for over 70 years. We have various mounting configurations, handle lengths, locking options, and light switch options available. For most applications, a standard over center hand lever or foot pedal lever is the best solution. However, where specific mounting or other custom features are required, custom solutions are available for any manufacturer looking to upgrade or add a brake lever to their vehicle.

Utilities

To keep life moving smoothly, utility companies trust their vehicles to be ready whenever and wherever they’re needed. Many of the tools utility vehicles use are driven by hydraulic systems that need to work flawlessly under pressure. To keep fluids flowing for these off-highway applications, these are the products Orscheln offers:

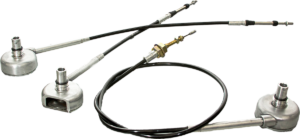

Fluid Level Indicators

This may sound like a very scientific way of talking about a dipstick, but there’s more to FLIs than meets the eye. The most commonly used product in this category is our Push 2 Seal™ FLI. While the simple design and ease of use of our Push 2 Seal™ systems are great for many off-highway vehicles, our twist-to-lock is an ideal choice for hydraulic systems on utility vehicles.

Push 2 Seal™

The Push 2 Seal™ Fluid Level Indicator design accommodates check applications for light- and medium-duty engines when the added robustness and cost of the Twist2Lock design is not warranted. You’ll typically find these used on generators and light-duty vehicles not designed for rigorous highway use.

This solution can be manufactured as either a standalone dipstick or a complete system. It can also be customized to ensure the exact specifications required for any vehicle on or off the highway. These are a perfect addition to the supporting features of a utility vehicle.

Twist2Lock™

To ensure the same accuracy and reliability in heavy-duty utility vehicles, Orscheln recommends the Twist2Lock™ Fluid Level Indicator. The innovative design is built to accommodate check, check/fill, or fill-only applications for many types of engines and transmissions. These are typically found on larger vehicles in industries ranging from waste management and sanitation to emergency response and material handling.

You may not think about your fluid levels. But if you like punctual packages and help when you need it most, thank a mechanic for checking the fluids with an Orscheln product! The world moves a lot smoother when the vehicles we trust get the fluids they need.

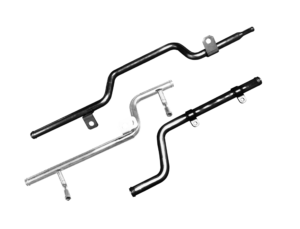

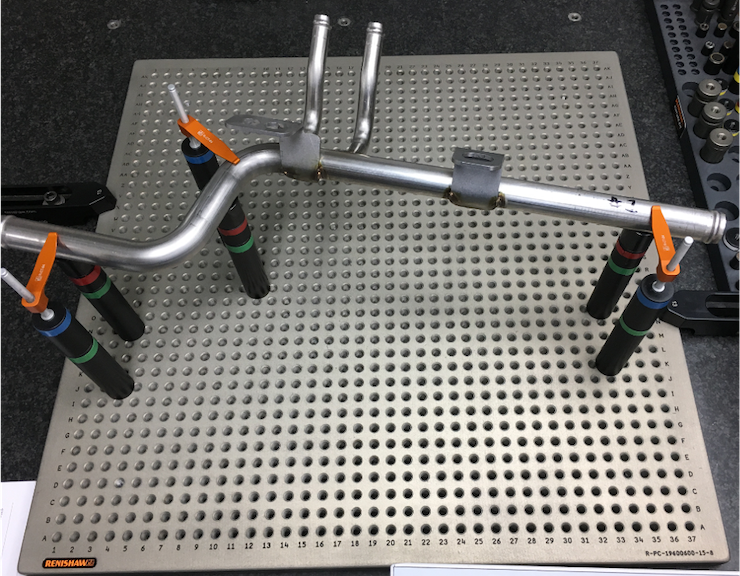

Fluid Transfer Tubes

It’s no secret that utility vehicles typically need a lot of various fluids. So while Orscheln’s FLIs maintain the right levels, our fluid transfer tubes make sure every drop goes where it’s needed. Here’s where you’ll find Orscheln’s FLTs on off-highway applications:

Oil Systems

What do you call an engine or a transmission that isn’t lubricated correctly? A paperweight is great for your desk, but not for your equipment. That’s why Orscheln designs and manufactures every tube to exceed the needs of our customers. Our engineers ensure that every bend, route, and fitting is designed to maximize the efficiency and longevity of engines and transmissions for on- and off-highway vehicles.

Compressed Air

There are times when a typical plastic or rubber hose just won’t do. To reliably route compressed air, many off-highway vehicles choose this transfer tube. Utility vehicles that use compressed air typically need constant and instant reactions to get the job done. That’s why OEMs around the world trust Orscheln. Our in-house testing environment ensures that every solution is up to our standards.

Coolant Returns

To keep machines cool under pressure, OEMs trust Orscheln once again. Each tube we create is made with high-quality steel and expertly engineered routing. With craftsmanship and quality materials, our fluid transfer tubing provides reliable coolant wherever a machine needs it.

You’ll typically find this type of tubing on lines running from radiators to internal cooling systems throughout the engine and transmission. Hard-line tubing is also very popular for electric cooling systems. With reliability, customization, and quality, almost every off-highway vehicle listed prior will use this tubing in one way or another.

F.A.S.T. Off-Highway Solutions

Orscheln’s F.A.S.T. distribution network is here to keep the world moving with parts directly from a trusted distributor. Each F.A.S.T. distributor is directly connected to our US-based headquarters. Every facility supplies the same quality solutions that have made Orscheln Products an industry name for decades.

Get cables, dipsticks, and more quickly wherever and whenever you need them from a trusted F.A.S.T. distributor! Talk to a distributor to find the right solution for you.

Watch: F.A.S.T. Facts With Jerry Frans

Keep Your World In Motion

While a lot of the world’s transportation is centered around highway driving, all roads end somewhere. To keep the world moving for off-highway vehicles, Orscheln Products is proud to be a trusted name for hundreds of OEMs all over the world. Whether you just need a part or a trusted partner in the motion control industry, our engineers are here to help. Find the right solution for your production the first time with an Orscheln engineer.