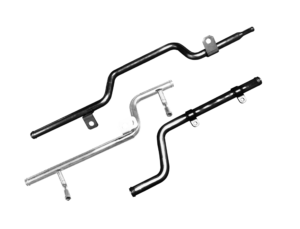

Hard-Line Tubes for High Pressure Tubing

Orscheln Products is a leading manufacturer of customized hard-line tubes for vehicle motion control systems and high pressure tubing. Effective for any fluid transfer or vehicle cooling, hard-line tubes are a superior alternative to traditional rubber or plastic tubing. Hard-line tubes are especially effective when implemented in Electric Vehicles (EV) construction and development projects.

At Orscheln Products, we work with clients and industries on the cutting edge of EV development. We have over 75 years of manufacturing experience, making us a global leader in mechanical control system solutions. Orscheln has earned international recognition for its quality. With operations in Europe, China, India, and North America, Orscheln is manufacturing the future of automotive engineering and motion control systems.

As we take time this February to focus on EV development and Orscheln Products’ commitment to zero-emission vehicle innovations, we wanted to highlight hard-line tubes. Orscheln’s hard-line tubing is effective for high pressure tubing applications, such as fluid transfer, coolant manifolds, transmission lines, and compressed air transfer. Since our hard-line tubes are capable of being built to custom specifications, Orscheln Products can manufacture them specifically to meet your needs. So, no matter the specifications of your EV project, Orscheln Products is the ideal manufacturing partner for you

In this blog, we’ll be diving into everything you should know about our advanced solutions to your high pressure tubing system needs. So, if you’re interested in learning more about Orscheln Products’ cutting-edge hard-line tubes, contact us to speak to an engineer or read on!

Orscheln Products Manufactures Hard Line Tubing

When the Orscheln family founded Orscheln Products in 1946, they were determined to provide lasting, innovative solutions to the automotive industry. We were a family business looking to help our neighbors. As we’ve grown, so too has the list of industries we support.

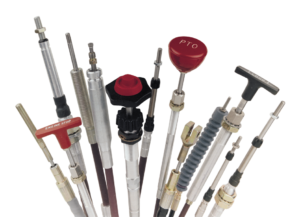

We provide comprehensive motion control systems solutions to On and Off-Highway vehicles, Military and Aerospace vehicles, Marine vehicles, and now EV/Zero Emission vehicles. We remain on the cutting-edge of our industry because our focus is on listening and collaborating with our clients. It’s not just about getting the job done; it’s about working together to meet their needs.

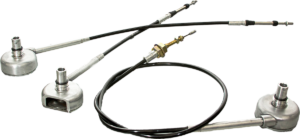

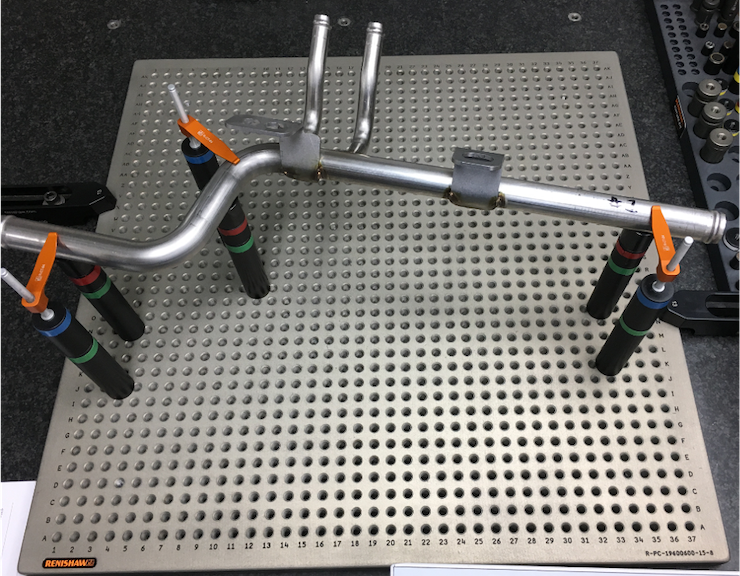

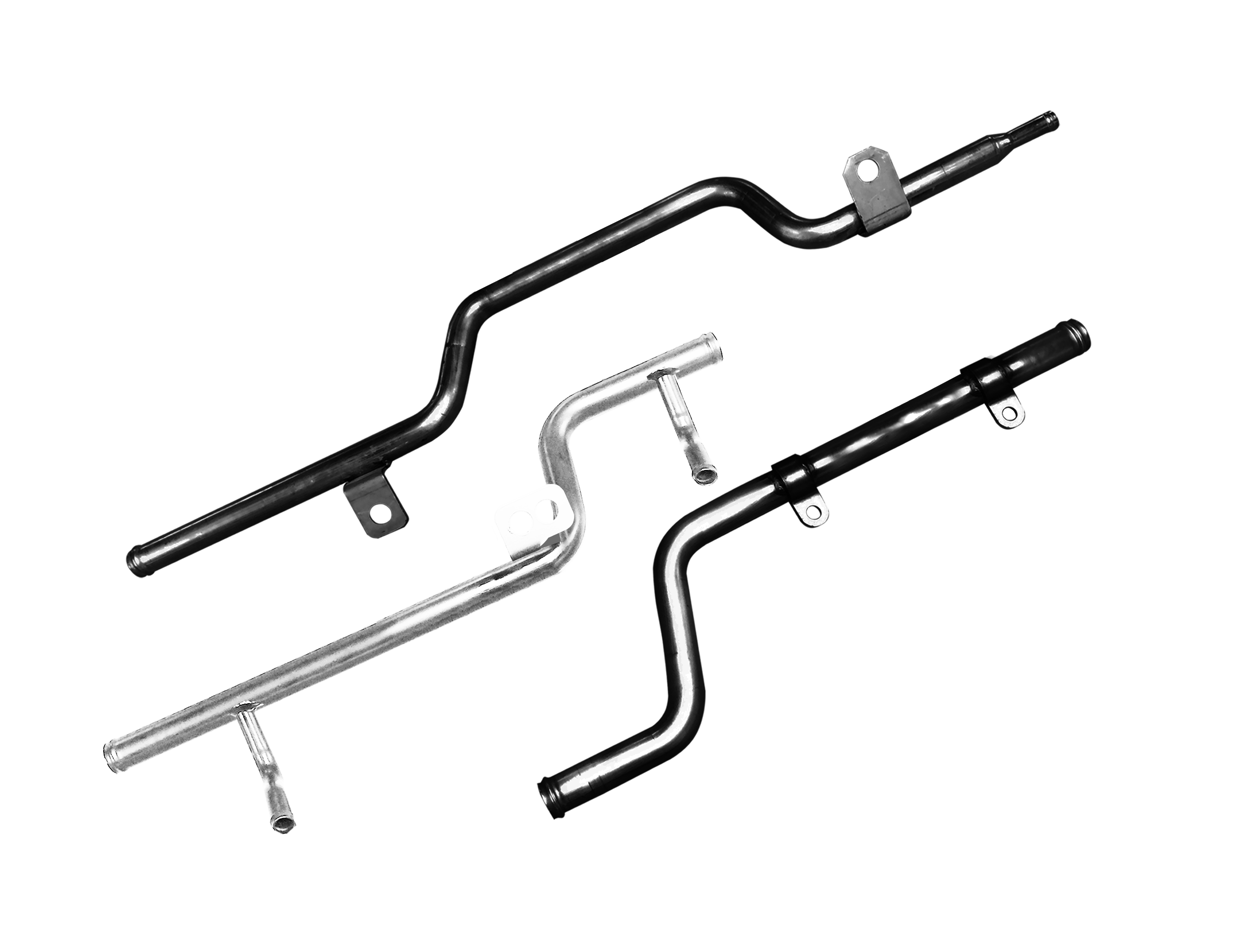

The primary highlight for our hard-line tubing is its intersection with various car utilities. Useful as fluid lines for cooling and as components for coolant manifolds, they’re also effective for transmission lines and moving compressed air. Their rigidity means they must be custom-built to the specifications of a project.

While this may at first seem limiting, their specialized manufacturing actually allows for high-efficiency integration into any high pressure tubing system. Within vehicle assembly, jumper tubes can be welded onto our hard-line tubes to allow for fluid transfer throughout the vehicle, not simply around the engine or battery. This makes Orscheln hard-line tubes effective, no matter your implementation needs. This gives them a broad range of utilities across vehicle design.

As Orscheln Products’ portfolio has expanded and our clients’ needs have broadened, hard-line tubes have provided necessary utility to a broad range of engineering projects.

Hard-Line Tubing for EV Development

When it comes to EV development, Orscheln Products’ hard-line tubes are more effective in high-pressure tubing than classic rubber tubing for a variety of reasons. Firstly, hard-line tubes are simply more durable than rubber tubes. Rubber tubing is flexible but easier to puncture and more likely to wear with time. On the other hand, hard-line tubes are sturdier, less likely to leak or rupture, and can last for the lifetime of the vehicle if properly maintained. This means that hard-line tubes provide notably greater value for the lifecycle of the vehicle, making them an invaluable investment in any EV development project.

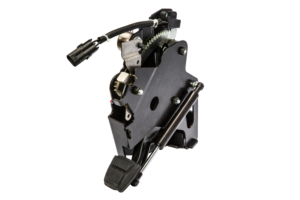

Secondly, though rigid and potentially more difficult to access when installed in the body of a zero-emission, hybrid, or electric vehicle, hard-line tubes are more versatile. This may initially seem counterintuitive, but with their durability and Orscheln’s ability to develop custom configurations, you can embed hard-line tubes anywhere in a vehicle.

OEMs can work alongside Orscheln engineers to build high pressure tubing manifolds that fit the exact needs of their project. And since manufacturing is customizable to fit project specifications, project engineers can effectively run hard-line tubes through a vehicle’s body to complement various internal systems.

Specialized for Battery Cooling

Most notably, hard-line tubing has proven incredibly effective when implemented as high-pressure tubing in EV projects, specifically for liquid battery cooling systems.

Liquid cooling systems are incredibly common within EV development, which is why we’ve designed hard-line tubes to help optimize the process. Using hard-line tubes, the basics of liquid cooling for EV batteries remain the same. Using the high pressure environment within the tubing system, the vehicle pumps liquid coolant through the hard-line tubes into the battery pack. In the battery pack, heat transfers into the coolant and then moves through the vehicle to a radiator, dissipating away from the battery. The coolant then continues through the high pressure tubing to repeat this process.

Orscheln’s hard-line tubing is effective in this process due to its rigidity, allowing for stable liquid transfer throughout the vehicle. This stability makes the cooling process more efficient and consistent, improving overall performance.

The Importance of Thermal Management

Orscheln Products understands the utility of effective thermal management for EV batteries. That’s why we manufacture our hard-line tubes to integrate seamlessly into an OEMs’ development projects with custom cooling manifolds.

After all, improper thermal management, or battery cooling, can cripple EV development. Features impacted by inefficient cooling include:

Electrochemical systems

Many EV developers use wet-cell batteries to power their vehicles, as they are easily rechargeable and efficient at holding and distributing power. However, these batteries can degrade with time without efficient thermal management, either with high pressure tubing or another system. Continued exposure to heat makes the process by which they distribute charge through the vehicle less efficient and less effective. This can lead to long-term degradation of the electrochemical systems that keep EV batteries functioning.

Charge acceptance

With decreased battery operation, charging a vehicle becomes less effective. This means it takes longer to charge your vehicle, and your battery’s capacity to hold charge decreases. It can also mean that the EV batteries are less effective in retaining their charge. This impacts every level of vehicular performance.

Safety

One of the major threats posed by ineffective thermal management is critical failure in the vehicle’s battery during operation. This can potentially lead to physical harm to passengers, other vehicles on-highway or on-site, and/or damage to the vehicle. Though highly unlikely, it is a risk posed by improper battery cooling and should always be taken into account during development.

Life cycle/replacement cost

High-quality thermal management also makes your zero-emission, hybrid, or electric vehicle more marketable. Low thermal efficiency degrades the quality, lifespan, and output of a battery. This means that any battery is going to wear down faster, requiring more frequent maintenance and replacements. Lower performance, a shorter lifespan, and higher replacement costs all negatively impact the marketability of EVs and EV products. After all, these issues make EVs less attractive to potential fleet owners, utility providers, or businesses looking to acquire more commercial and occupational vehicles.

Driving distance

Improper thermal management can quite literally decrease the quality and usability of your EV. Poor cooling performance can severely impact an EV battery’s performance, charging efficacy, and charge retention. This means, naturally, that it affects the ability of a zero-emission, hybrid, or electric vehicle to travel as far on a single charge.

Orscheln Products understands the necessity of high-quality, dependable components when developing EV innovations. As an OEM, you should be able to count on your contract manufacturers to deliver assembly solutions in a timely manner. That is Orscheln Products’ area of expertise.

No matter the type of battery implemented in EV development, Orscheln Products has the expertise to contribute to the success of an engineering and construction project.

Orscheln has the Broadest Range of Capabilities & Products.

If you’re a business looking for motion control system experts to supplement your EV development or liquid transfer needs, you’ve come to the right place.

Orscheln Products is unwaveringly committed to providing our service markets with the absolute best in expert, dependable, and customizable manufacturing support. Our team is the leading manufacturer of motion control system components and solutions internationally. You can count on the experts at Orscheln to provide exceptional service and lasting motion control system construction, development, and engineering solutions.

With global reach and experience managing projects across a wide variety of industry niches, you can rest assured that Orscheln Products has the capabilities to make your development project a success. We have years of experience supporting EV development and implementing hard-line tubes in a broad range of high pressure tubing systems. This makes us an invaluable resource for OEMs working to optimize project engineering and assembly.

So, if you’re an OEM looking for high-quality hard-line tubing for your EV or manufacturing project, look no further. At Orscheln Products, your project is our priority! Contact us today, or take advantage of our virtual chat with an engineer service.