Providing the right throttle pedals to accelerate your production.

Picture the cab of any piece of equipment. On highway, off highway, heavy duty, light duty. It doesn’t matter. You’re probably seeing a gauge cluster, a wheel, and maybe a few levers. These are all essential components. But most essential of all is your throttle pedal, the connection between you and the heart of the machine.

Orscheln Products has a history of creating essential solutions for OEMs. As manufacturers evolve, so do our solutions. When you think of exciting emerging technology, you may not think about throttle pedals. But once you talk to an engineer, you’ll see why Orscheln is on the cutting edge of every need for manufacturers.

What makes up our throttle pedals?

While a throttle pedal design may seem straightforward, there are so many things we account for when designing your solution. We use your specifications to fit your design with the correct pedal. We also walk through real-life applications to make sure your design keeps engineers and customers satisfied.

Materials we use

All of our throttle pedals are made with injection molded, glass-reinforced plastic. We also include nylon pads for the pedal’s shoe. We include cutting-edge drive-by-wire systems and hall effect sensors to bring our throttle pedals into the 21st century.

Hall Effect Sensors

We utilize industry standard dual hall effect sensors in all of our throttle pedals. The sensor is housed within the throttle pedal itself. Which results in a simpler, sturdier design that’s an easy addition to any application.

Every sensor we use is calibrated and tested on site. We program and inspect all of our throttle pedals on our factory line. This ensures that every product is ready to go on delivery. We also include this process in even more complex sensors as well.

CAN Sensors

The next evolution in vehicle operating technology is here. Controller Area Network sensors, or Control Area Network (CAN) sensors is the latest sensor technology we are implementing in current designs for our clients. These sensors work to connect your throttle pedal to the “brain” of your vehicle.

Orscheln uses the ever growing standard of CAN communication for our sensors referred to as J1939.

This standard allows the sensor to be monitored by other systems in your vehicle and synthesize control with the entire vehicle. When we customize your CAN throttle pedal each connected component can “talk” to each other on the network to maximize efficiency and improve overall performance.

Customizability

All of the physical aspects of our standard throttle pedals are specifically designed with the manufacturer and operator in mind. Our engineers are able to customize the sensors to work with specific vehicle management systems and engines any application. We can design new pedals for high volume applications where a highly customized solution is required.

This is why manufacturers choose Orscheln for their solution. We can mass-produce floor mounted, or suspended throttle pedals with the correct specifications right off the shelf. As well as pair a throttle pedal and brake pedal to create a custom cluster solution if needed.

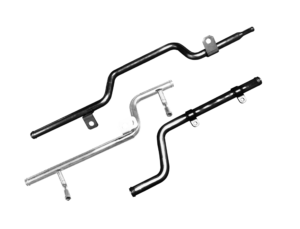

Floor Mounted Throttle Pedals

Floor mounted pedals are most commonly found in off-highway machines. Below, you’ll find our general and mechanical specifications.

Specifications

| Functional |

|

| Weight of Pedal |

|

| Validation |

|

| Electrical Specifications |

|

As with any part, our engineers can customize your solution to your needs. If you require any spec not listed above, talk to an Orscheln engineer about your product.

Global Suspended Throttle Pedals

For most on-highway applications, manufacturers choose our suspended throttle pedals. This is where our engineers take the real world into consideration. With new motivations, regulations, and real world use, suspended throttle pedals have become the go-to solution

We produce two different suspended throttle pedals to expand the flexibility of what we can provide manufacturers. The key difference in both is found in the output. On the newly released Global II pedals, Global II pedals are a simple reliable low part count evolution of our Global I pedal

Global I

The main reason manufacturers use our Global I pedals is for their flexibility and durability. This product can be used in many types of equipment for on or off-highway use. With its versatile bolt on sensor architecture the Global I can accept our standard hall effect sensor or our CAN sensor. Installation, and setup is a snap. Our general and mechanical specifications are as follows.

Specifications

| Functional | Actuation Force applied perpendicular to the pedal pad surface and at a point 5.6 in (142 mm) from the centerline of the pivot axis

|

| Weight of Pedal |

|

| Validation |

|

| Electrical Specifications |

|

Global II

Manufacturers choose Global II option when they want a simpler design and to minimize part count in their inventory system, and Global II fits exactly this need. Global II pedals are a simple reliable low part count evolution of our Global I pedal. Below are the specs for this specific product.

Our general specifications account for things like material requirements and operating conditions. If your solution requires anything outside of these specifications feel free to talk an engineer about your specific needs.

General Specifications

|

|

Environmental Conditions |

|

|

|

The mechanical specifications of our floor mounted pedals are based on industry standards for most manufacturers. If you need any spec outside of these standards, contact us to learn about customization options.

Mechanical Specifications

|

|

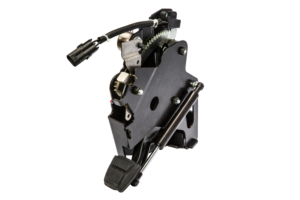

Many applications require both a brake and throttle pedal. While we can also produce individual brake pedals, we go the extra mile for manufacturers. Orscheln Products makes it easy.

Throttle Pedal Clusters

We can produce clusters for your application as well. Sometimes referred to as pedal boxes, these clusters include both throttle and brake pedals as well as mounting hardware. This application is largely used in fleet and high volume manufacturing of on and off highway vehicles. Manufacturers choose this option to minimize part count and make installation, setup and operation simple.

Our throttle pedal clusters are available with Global I and II suspended pedals. As with all of our products, these can be custom fit and calibrated for any cab and any engine. This is a common order for customers looking for a complete, ready to work product from our factory.

Certifications

All of our products are certified and tested regularly to maintain industry standards and product quality. We certify our products to exceed standard quality and environmental standards.

All of our throttle pedals are FMVSS105 compliant and IP67 rated. We exceed industry standards to provide a reliable product that can be used in various applications. With so many options and specifications it might be difficult to find the right product for your design.

What to know before ordering your throttle pedals.

There are many manufacturers use our pedals every day. So after pouring over our specs and finding your solution, many customers come to us with a grocery list of things they want to talk to our engineers about. So here are a few key things to keep in mind when you contact us.

Precise Designs

CAD files or digital blueprints are the preferred methods to submit your designs. This ensures that we can accurately and quickly design your product. We will also require engine specifications to calibrate your pedals to your application.

Lead Time

While our production line meets and beats deadlines every day, it’s important to have realistic production expectations. Due to the design of our pedals, many floor mounted and suspended pedals are available off the shelf. But make sure to provide your engineer with specs before choosing a standard production option.

Volume of Order

Many of our products can be produced in short runs, or large quantities. When ordering your throttle pedals make sure that your desired option is the most efficient for your production line. Our engineers can give suggestions based on your desired volume and manufacturing capabilities.

Accelerate your production with Orscheln.

Orscheln has been supplying OEMs with trusted parts since 1946. So our team knows a thing or two when it comes to keeping the world moving. When manufacturers are keeping a fleet on the road or designing the latest EV technology, our throttle pedals are the industry go to for a reason.

Talk with an engineer to start building your solution. Or contact us to accelerate your production with a custom solution from Orscheln Products.