Capabilities

Orscheln Products Engineering is comprised of a dedicated team of professionals committed to listening to each customer and delivering solutions that serve customer needs and exceed expectations.

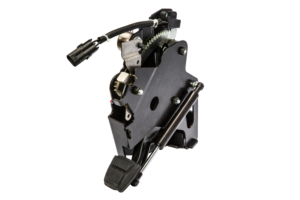

- Mechanical Design

- Electrical Hardware

- Software

- Test

- Project Management

- Manufacturing Engineering

- Tool/Fixture design and build, End-of-line testing, Kaizen, Error-proofing assembly processes

- DFARs, IMDS, REACH compliance, PMA submissions, FAA conformity

- In-house CAD/CAE/FEA

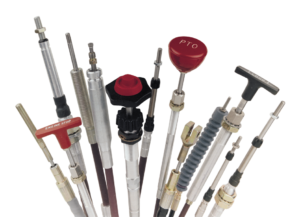

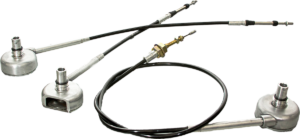

- Design, manufacture, and test of ferrous, non-ferrous metals, plastics and corrosion coatings/treatments

- Standard product as well as custom design capabilities

- Customer experience in the On -Highway, Off-Highway, material handling, ground support, Defense, Marine, and Aerospace markets

Testing

Every Orscheln Products Test Engineer is devoted to ensuring each Orscheln product is designed to function at the highest level of integrity. Orscheln Products’ 15,000 sq. ft. lab houses all of the testing operations built to prove each product meets internal and/or customer specified requirements.

Environmental

Temperature/Humidity:

- Thermal Cycling: -70°C to 170°C

- 10% to 98% Relative Humidity

- Thermal Shock: -70°C to 170°C

Vibration:

- Sine, Random, Shock, Accelerated, & Combined Environment

Dust:

- SAE J1455 Optional Method, Suspended

Chemical

Various specifications and customer specific requirements

Corrosion/Humidity

Applicable Specifications:

- ASTM D870

- ASTM D1735

- ASTM B117

- ASTM D2247

- GM9540P

- GMW14827

- GM4465

- SAE J2334

- GM4465P

- GM4298P

Mechanical

Durability/Life-Cycle/Efficiency

Ultimate Strength

Gravelometer

Tensile testing up to 60,000 lbs

Custom test applications with in-house design/fabrication capabilities

Rockwell and Micro-Hardness

Data Acquisition

Complete machine control with real-time data acquisition

Custom programming

Remote notification/connectivity

Cleanliness

Various specifications and customer specific requirements